Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

While a lot of robotic companies are building human dimensions, or working to automate the factories, Microfactipory It is instead of trying to think great building small.

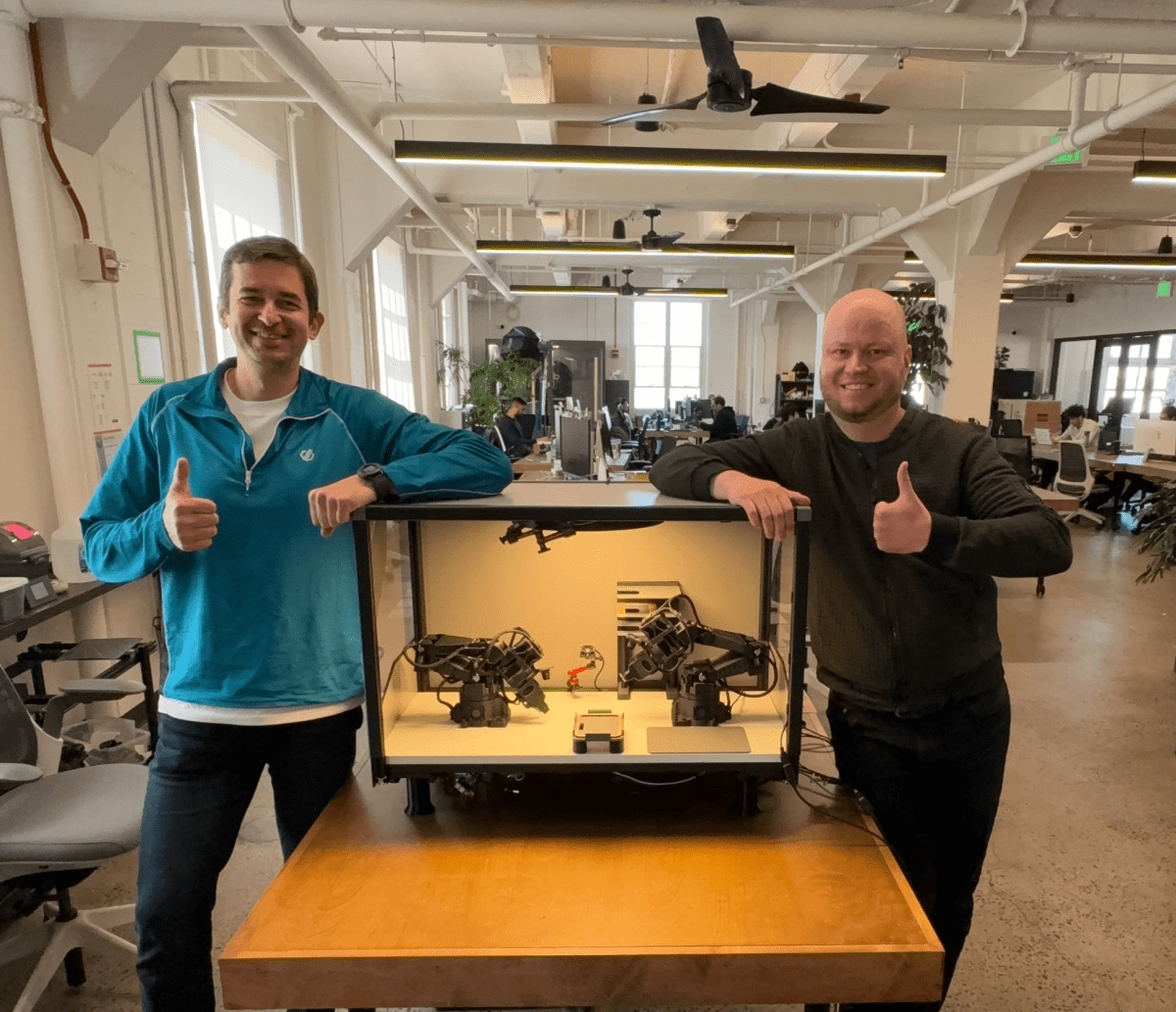

San Francisco Baselite in San Francisco build a general job kit, tablet kit that is of the size of my siberous dog rig. This compact factory includes two robotic weapons and can be trained by human demonstration, and because of the ai.

“General purpose books, but it is not necessary (to be Igor Kulakov and Czech, and the screen, and this and that and it is and can do more simple, in the munts and on the mo.”

Instead of selling individual robots, microofaltory system comes as a closed work station, allowing users to watch the real-time manufacturing process. Compact-in-box factory is conceived for graphic tasks as circuitable circuit, component balance, and rolling cable. Users can train the robbers for the physical way through a complex movement – a dead approach that Kulakov says works for the sequences in intricate madness.

“Usually PIR brings 7th, but in this way, the robot I understand.” He has to be aware of this people and it will be aware of a pattern and it will be working on this model and to work in this model and do

Kulakov experience with traditional fabrication helped to disappear the idea behind microFactory.

He and his co-foundation, Viktor Petrenko, adequate bits, a dummy firm that made portable lighting equipment. Kulakov said it was difficult to form new employees on how to complete the manufacturing process correctly. When advances in AI has the following possible to automate this type of work, decided to jump on opportunity.

Techcrunch event

San Francesco

| 0.

October 27-29, 2025

Kulakov and Petrenko launched microFactory in 2024. He took about five months to build their prototype. Now the company is looking for clients to have the machines for different applications, including electronics and also to transform the lumbers to France for owargot.

Microphathers just raised $ 1.5 billion funding of $ the round values the inexpensive in a $ 30 million evaluation.

Kulakov said the company thinks about using funding to build and ship their units. The company is currently converting their prototype in a commercial product I hope to start shipping in about two months.

The company also thinks of doing some hunts and continue to improve their technology, including your patterns running below the hood.

“Our growth is related to a building hardware, so establish the purpose of setting 10x each year,” Kulakov said. “In the first year, we should produce 1,000 robots, (about three hours, we have the ability to do. Then, (we want) do more and more