Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

The new 3D Microfactors’ new era helps to transform the waste plastic into “high competitive” products suitable in the construction industry, reports Veena Sahajwalla, Professor and Founder of the Sustainable Materials and Technology Center (Smart).

Speaking in front of Mandy Drury CNBC at the Sydney Innovation Sydney Innovation Schneider Electric summit, Sahajwalla stated that manufacturers should direct their thinking.

“It’s not about saying, well, I do it because its green. In fact, it must be the last. The first thing that should be profitability, does it work? Does it show the right performance?” she said.

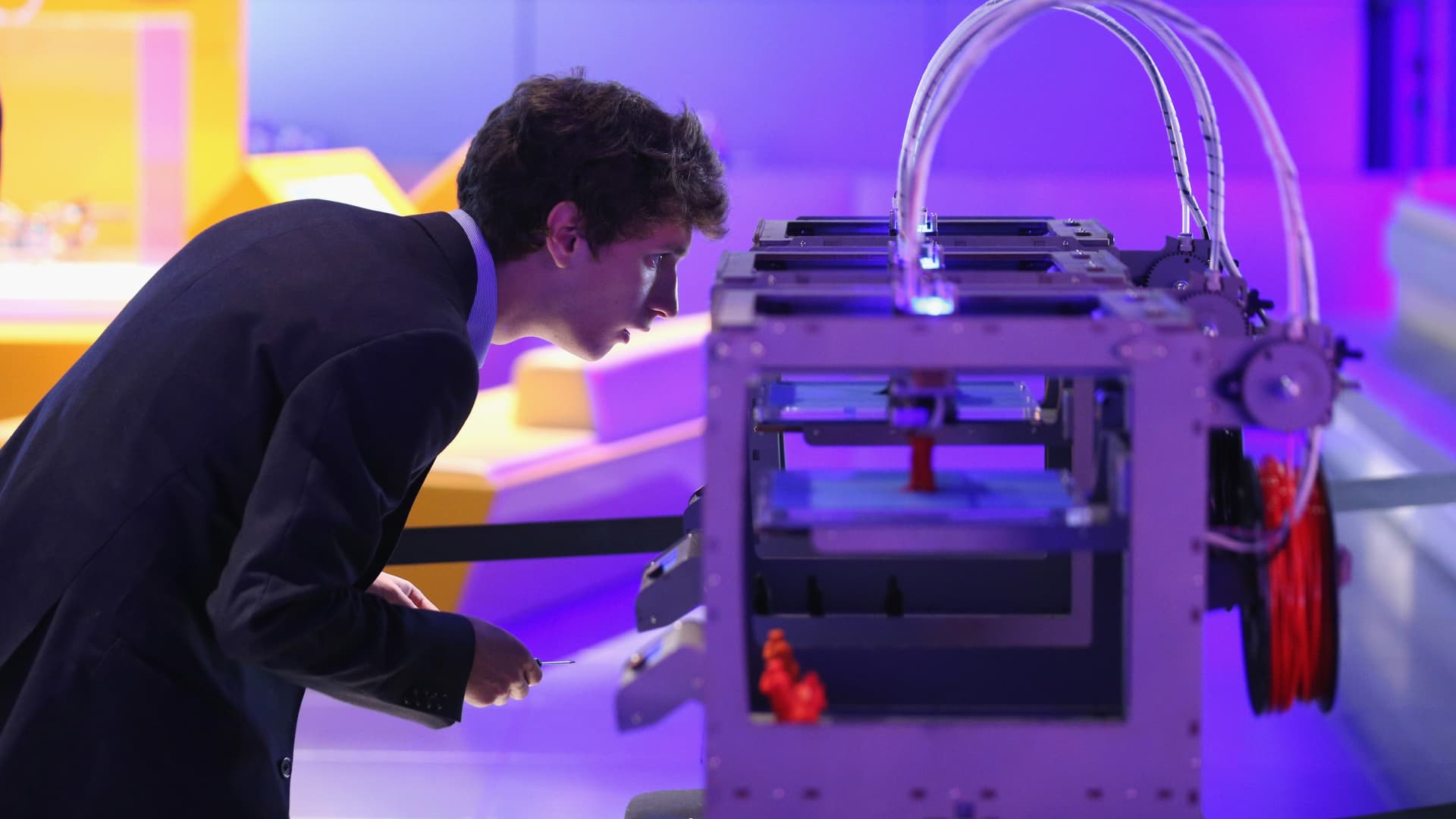

Such thinking pushed Smart to create plastic threads made of 100% waste derived from “all old printers”.

They are built in a hyper-lacked, heavily automated “microfactor” for the production of personalized products.

“If this (plastic made by waste) can now be submitted in a 3D printer, you can actually print a number of products?” she said.

One of these products is “clips” – or blocks – used in construction and construction projects.

“Imagine that all construction and construction projects where you need plants and imagine if you have to wait a long time to get these parts and components,” Sahawala said.

Big costs at factories during construction projects means that companies often buy them.

3D Smart Alternative, built in Sydney microfactors using plastic threads made of old, plastic waste, may eventually reduce the costs, Sahaivol says.

“Can you literally talk to the local microfctor and say if I can do it at a comparative price and correct form?”

“It was here that microfactor technologies came here. To truly close the gap between what is considered as waste from one hand, and on the other hand, do something high performance, high technology and competitively closing the gap.”

Autonomous trucks and buses operating on pure energy based on hydrogen are on the reason for the impact on the roads, thanks to the technology, which is still in a rudder.

Scott Brown, head of the director of pure hydrogen, told CNBC that his firm now has hydrogen, which works in the city of Adelaide, which throws out “is not diesel pollution, which can harm your health if you inhale it, as well as less noise.

It predicts a fall in prices for fuel elements in the next 10 to 15 years.

Car manufacturers Honda. Toyota and Hyundai Already accepted more engineering of fuel elements.

Fuel elements belong to the use of hydrogen or other fuels for clean electricity.

“There are not many materials here. It’s like a PC, and you put it – in our case – a truck or a bus,” Brown said.

Due to its increasing economic production, the prices for fuel elements have decreased by “about 50% in the last three years,” he added.

Brown predicts that pure energy cages will be “sharply” in the next decade when Chinese companies are taking more vehicles operating on hydrogen.

According to Figures published by South Korean analysts, SME research team In November, the sale of commercial vehicles in China exceeded the amount of purchases worldwide.